Metro Napkins

General information

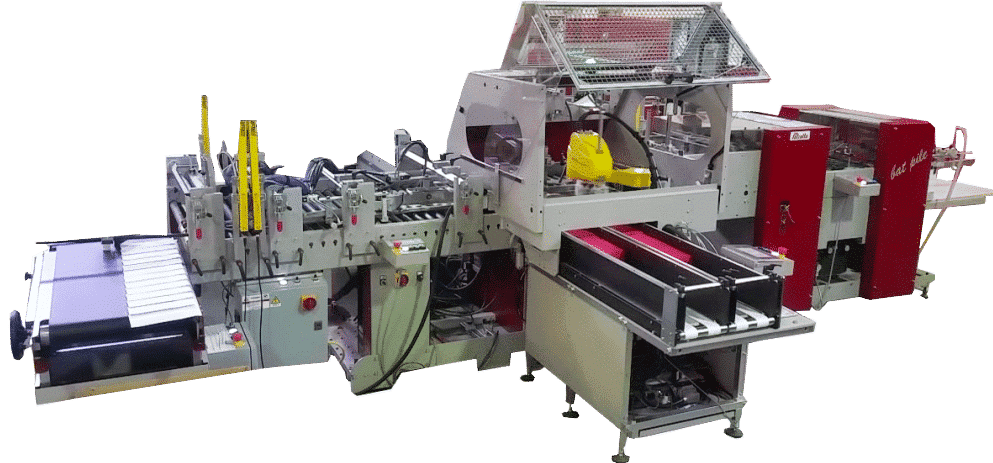

Cutlery envelopes, perfectly folded. Automatically.

Metro Napkins automates the full production of cutlery envelopes with folded napkins inside — in a single step. Developed in collaboration with manufacturers in the sector, it simplifies what is traditionally a multi-stage, partly manual process into one continuous, operator-friendly line.

The system folds the napkin directly inside the machine (in two or three parts), eliminating the need for pre-folded napkins and enabling the use of standard sizes from a wide range of suppliers. This means more freedom in sourcing materials and lower production costs.

Thanks to its double-line robotic feeding and optional glue application, Metro Napkins handles different materials and speeds with ease. The double front fold of the envelope ensures a clean, professional finish without the need for double-sided printing, reducing time, waste, and complexity.

With Metro Napkins, productivity increases while manual steps are eliminated — for a reliable, high-quality product every time.